InTeMP will participate arranging FMT DAY event in Nivala 17.05.2022. The theme day of the Future Manufacturing Technologies (FMT) research group of the Kerttu Saaalasti Institute of University of Oulu will focus on the rapid heat treatments made possible by modern induction heating technology and their utilization.

The content of the event to be held at Nivala Technology Center Nitek (Tupa Hall, Pajatie 5, 85500 Nivala) will be divided this time into the Finnish and afternoon English sections. ELME Studio Open Doors 8: 15-11: 00 and e.g. induction line demo in the afternoon. It is also possible to follow the event remotely.

Check out the program and schedule of the event in more detail in the invitation or at event website.

The event is free and open to everyone. Coffee service!

Registrations by May 13, 2022 to sanna.viirela@oulu.fi

When registering, please indicate whether you will attend the event remotely or on site. We will send a participation link to remote participants the day before the event.

Warm Welcome!

Second induction line was transported and istalled into LUND. Installation was completed during first day and second day was used for training. Line will serve as a test unit for developing more efficient high frequency induction system.

A video introducing the new induction line developed in the InTeMP has been released. Watch the video below or on the FMT youtube channel.

Researchers from Lund university visited Nivala facilities for induction heater testing. Purpose of the test was to measure beahviour of the induction power units in actual use case with long continuous heating. Testing helped to determine efiiciency of the current system and to make design corrections for the next incduction setup consisting 4 power units. According to the tests additional 50-100% increase in the heating power could be achieved with the change of transfomers in current setup.

Heating tests were performed for the 4x40mm specimen up to 800 C temperature. Below is a video of a test heating run.

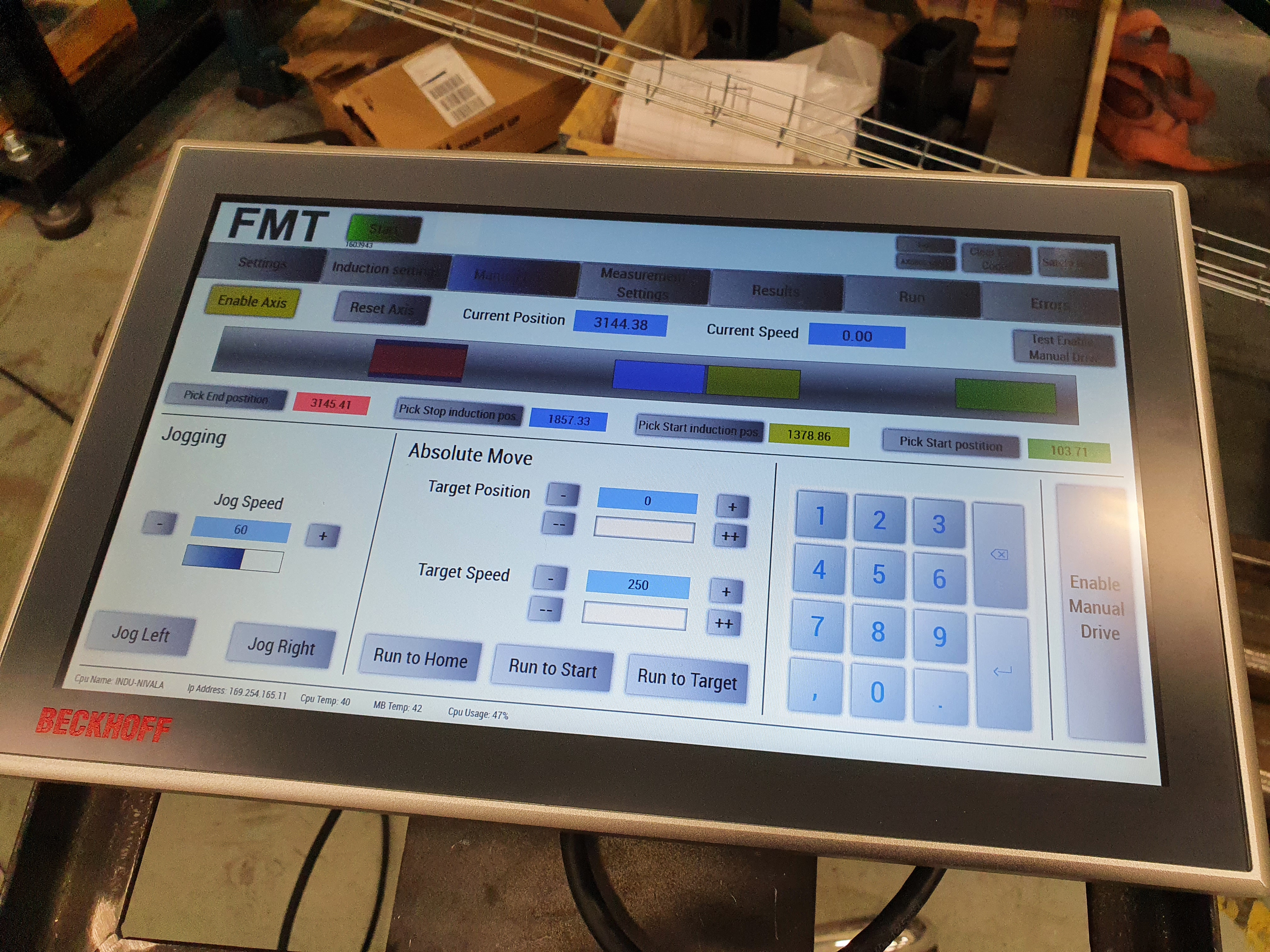

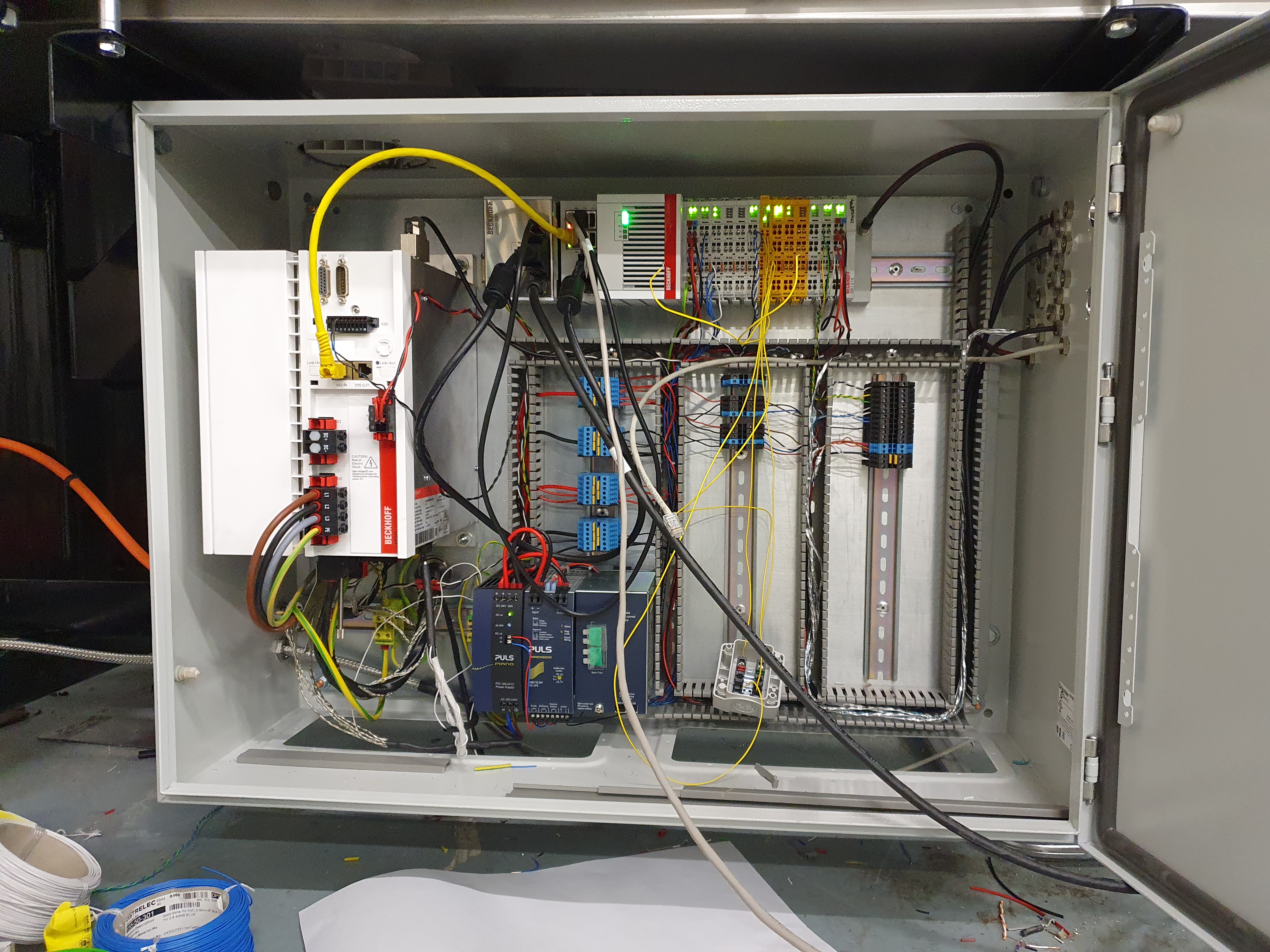

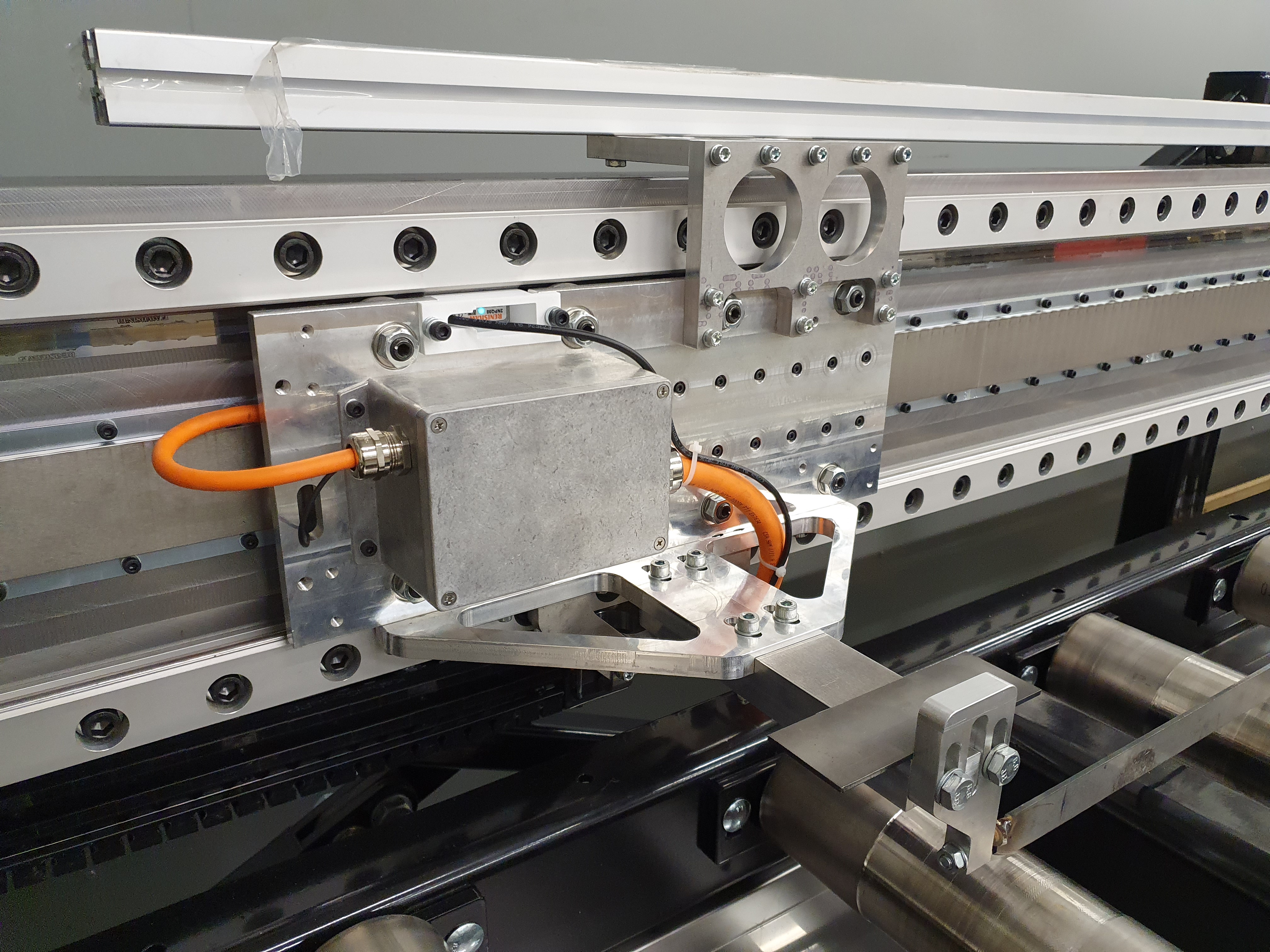

Assembly of the Nivala induction line is finished including first induction heating setup consisting of two 15 kW power units. First heating tests with the line were performed with positive results. The system functioned in the tests as expected which gives a great feedback that the project is on the right track.

Next steps on the project are focusing on the comprehensive testing of the system and development of the control software so that the line will be safe and reliable to operate. Software development will be done by project personnel, which ensures fast and agile testing, development and implementation of new features.

The frames for the two research induction lines have been assembled and next be painted. First tests on the line mechanics are planned for August. One of the lines being built will be placed in Nivala, and the other at the Lund University.

The Swedish partners have performed the first induction technology experiments with two parallel connected power sources successfully. Development on the heating technology will continue with redesigning few of the components in order to improve the equipment efficiency.

Once the mechanical testing and new version of heating technology are ready, the machinery will be installed onto the induction line and research work can get started. In the first phase the research line will be fitted with a two-power source induction apparatus with a total power of 30 kW. The University of Oulu will focus on material research, whilst the main purpose for the line at then Lund University is to operate as a test line for the heating technology development itself.

InTeMP's work started last fall with the designing of the new induction line for research purposes. This line is now in the process of being built. First experiments on it will likely take place in May, if no setbacks occur in the schedule. Lund university is also currently developing a new type of high frequency induction technique for the research induction line. The technique is currently in the preliminary testing phase.